White Big Printed Food Grade PP Woven Sack for Sugar Packaging with Brc Certified

Basic Info

| Application | Food, Chemical, Stockfeed Packaging |

| Feature | Moisture Proof, Recyclable, Portable |

| Material | PP |

| Shape | Tubular Bag |

| Making Process | Plastic Packaging Bags |

| Raw Materials | Polypropylene Plastic Bag |

| Bag Variety | Top Opened Bag |

| Print Type | Multicolor Printd |

| Top | Top Cool Cut |

| Bottom | Bottom Stitched |

| Fabric Color | White Color |

| Bag Size | Size Customized |

| Loading Capacity | 5kg 15kg 20kg 25kg 40kg 50kg |

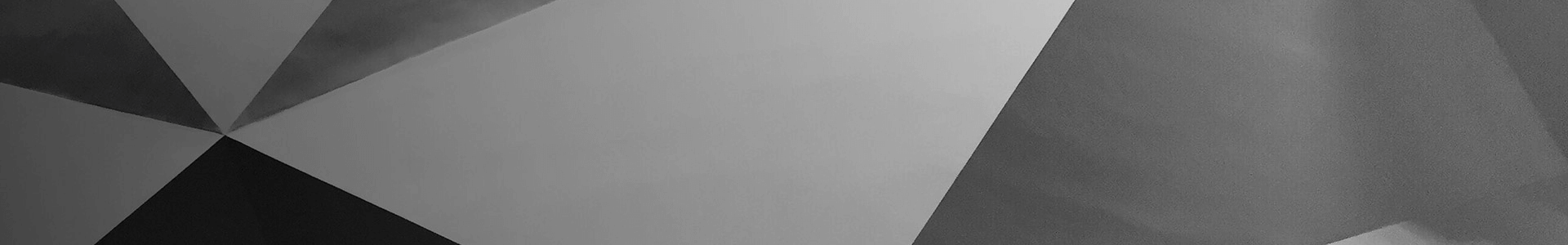

| Handle | D-Cut Handle or Plastic Handle |

| Fabric | Anti-Slip |

| Surface | Water-Proof |

| Outlook | Product Window |

| Bag Type | Side Gusset |

| Bag Name | Wpp Bag |

| Pack | Heavy Duty |

| Usage | Industrial Use |

| Option | Back Seam |

| Transport Package | Bale or Pallet |

| Specification | Customizable |

| Origin | China |

| HS Code | 630533 |

| Production Capacity | 300 Million PCS Per Year |

Product Description

Detailed Photos

PP woven bag with outside BOPP film laminated.Nice gravure printing D-cut portable handleThese are available in a wide range of standard and custom designs and sizes.

Product ParametersNo. | Item | Specification |

1 | Shape | Tubular or back seam |

2 | Length | 300mm to 1200mm |

3 | width | 39mm to 700mm |

4 | Top | Hemmed or open mouth |

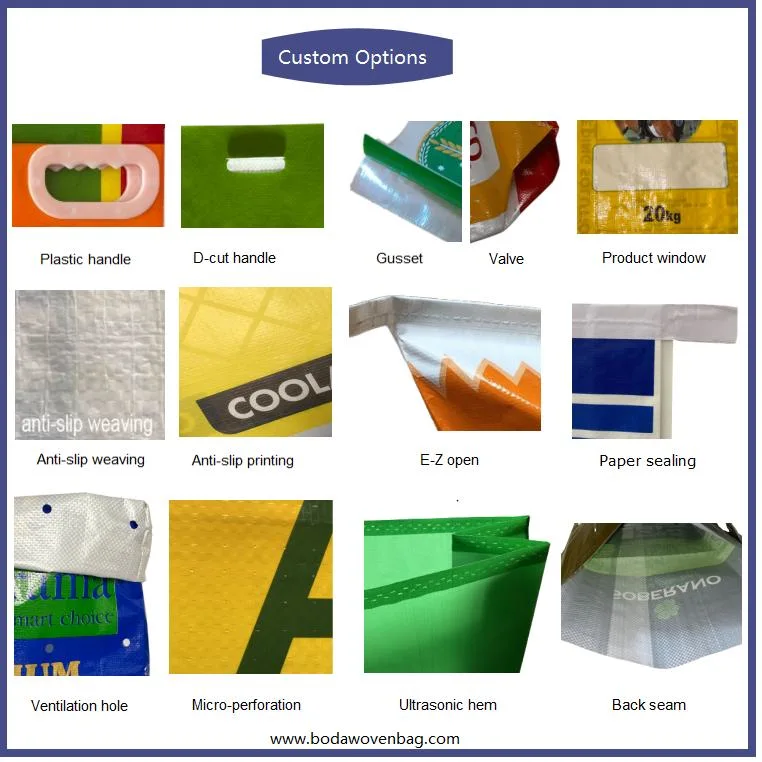

5 | Bottom | Single fold, single stitch; single fold, double stitch; double fold, single stitch, double fold, double stitch |

6 | Printing type | Gravure printing on one or two sides, up to 8 colors |

7 | Mesh size | 8*8, 10*10,12*12, |

8 | Bag weight | 50g to 120g |

9 | Air permeability | Depends on customers' requirements |

10 | Fabric Color | white, yellow, blue, or customized |

11 | Fabric Weight | 55g/m2 to 220g/m2 |

12 | Fabric treatment | Can with aluminum foil laminating, Or with pearlized film composite |

13 | PE lamination | 14g/m2 to 30g/m2 |

14 | Application | For packing the rice, flour, grain and seed, stock feed, animal food, pet food, granule, etc |

15 | Inside liner | HDPE or LDPE inner liner |

16 | Characteristics | Puncture and tear-resistant, Moisture-proof, easy for pallet pack, more sides display on the shelf. eye-catching appearance |

17 | Material | 100% virgin polypropylene |

18 | Optional choice | back seamed, the bottom can be block bottom |

19 | Packaging | about 500pcs for one bale or 5000pcs one wooden pallet |

20 | Delivery Time | within 25-30 days for one 40HQ container |

According to our customer's specific requirements, we can make bags in multi-function, For bags with portable requirements, we will provide handles: the plastic handle or Die punched handle; For bags with anti-slip requirements, we will print anti-slip adhesive or weave the fabric with anti-slip effect; For users with high requirements on moisture resistance, inner PE liner or inside lamination/coating are available for choice;... There is no question that is too small, no task is too big, all the demands we will take seriously and find the best solution for you.

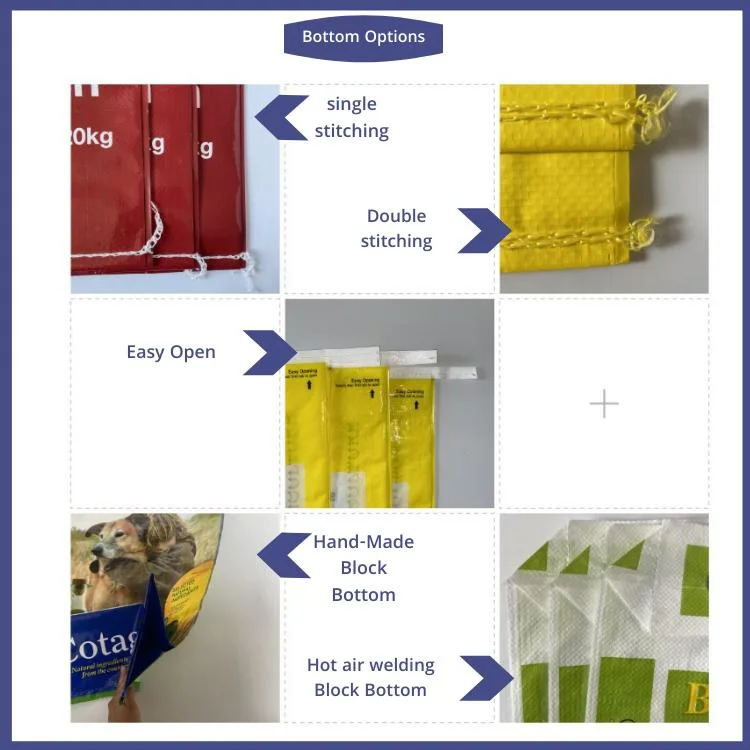

Production Process

As a professional manufacturer of the Block Bottom Valve packaging bag, we make our bags:1. In 100% virgin raw material2. Eco-friendly ink with the good fastness and bright colors. 3. Top grade machine to make sure a strong break-resistance, peel-resistance, stable hot air welding bag, make sure the utmost protection of your materials. 4. From tape extruding to fabric weaving to laminating and printing to the final bag making, we have strict inspection and testing to make sure a high-quality and durable bag for end users.

Our Advantages

1. Factory produce factory export. 2. Engaged in this industry since 1983, with more than 39 years of experience3. Top-grade equipment has been introduced since 2009 to ensure higher quality and reduce the overall cost for customers. 4. Occupied a total of 160,000m2 of production area and can make sure an annual output of more than 500 million bags.5. Professional design team, well-cooperated cylinder workshop, with sufficient experience in handling more than 6,000 kinds of bags, to meet the unique needs of customers

6. Good reputation, we aim for a long and stable relationship with our valuable customers.7. Professional Services*pre-sale serviceAny of your questions will be taken seriously and offer you reference opinions. * In-sale serviceMake you posted on the production progress with on-site follow-up for each production step. * After-sales serviceWe are responsible for every bag we exported. Feel free to contact us in case any questions you may have. We will work and solve your problems timely.

Packaging & Shipping

Packaging:Bale packing: 500,1000pcs/bale or customized. Free of charge.Wooden Pallet packing: 5000pcs per pallet.Export carton packing: 5000pcs per carton.Loading:1. For a 20ft container, will load about 10-12 tons. 2. For a 40HQ container, will load about 22-24tons.